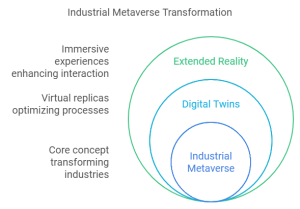

Imagine a new world where factories, plants and cities can be managed from a digital environment that is almost as real as the physical one. The industrial metaverse is making this new world possible, changing the way companies manage their operations, optimize processes and ensure sustainability. At the heart of this revolution are digital twins, a technology that, combined with extended reality, is redefining industry as we know it.

What do we mean by industrial metaverse?

The industrial metaverse differs from the general metaverse by focusing on the integration of emerging technologies such as augmented reality (AR), virtual reality (VR) and, especially, digital twins. This advanced digital environment allows companies to simulate, monitor and optimize their operations in a virtual space, where real-time data is integrated to make informed decisions.

The applications are varied: from smart factories that can predict failures before they occur, to digitized cities that allow constant and accurate monitoring of their infrastructure. The industrial metaverse is not only changing the way industries operate, but is also opening up new opportunities for innovation and efficiency.

The best tools for the industrial metaverse

In the industrial metaverse, digital twins become a fundamental tool for optimizing operational efficiency. Imagine a manufacturing plant where each machine and its performance can be visualized in real time, anticipating failures and adjusting production parameters to maximize output. Companies in industries such as automotive, manufacturing and energy are already using this technology to reduce downtime and improve productivity.

Benefits of the Industrial Metaverse and the Digital Twins

- Process optimization: The industrial metaverse allows companies to simulate and visualize work environments in real time, adjusting parameters and improving efficiency immediately.

- Improved safety: Simulating critical processes or hazardous environments in a digital space reduces risks to workers, as procedures can be tested and adjusted without putting people at risk.

- Sustainability: ESG (Environmental, Social, and Governance) policies benefit greatly from the use of digital twins, since they can

What lies ahead?

The industrial metaverse is just beginning, but its evolution promises to be rapid and disruptive. Companies that adopt these technologies will be able to not only optimize their current processes, but also create new ways of operating that will allow them to stand out in their industries. Digital twins will continue to be a central part of this evolution, acting as a bridge between the physical and digital worlds, and facilitating a convergence of data that will drive efficiency and sustainability.

References:

- Foundtech – Digital twins

- Inmersis – Changes in new technologies

- Advancedfactories – Simulation of digital twins VR/AR transforming industry